Robots for Manufacturing: Streamline Material Handling

Optimize your manufacturing operations with material handling automation solutions designed to improve efficiency and reduce costs.

Contact Form

Streamline Manufacturing with Material Handling Automation

Our robots for manufacturing are designed to optimize your production processes through cutting-edge material handling automation. The S100 robot efficiently transports raw materials and finished products, minimizing downtime and ensuring seamless workflow transitions. By integrating our automation solutions, your team can concentrate on core production tasks without disruptions. Contact us today to discover how our robots for manufacturing can transform your operations.

Optimize Manufacturing Processes with Reliable Robots

Manufacturing businesses in the GTA can now optimize their production lines with Reliable Robots’ automation solutions tailored for the unique demands of manufacturing environments. Our S100 material handling robot is ideal for automating the transport of raw materials and finished products, reducing downtime, and ensuring seamless workflow transitions.

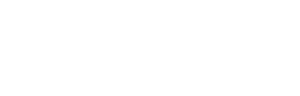

With the S100, your team can focus on core production tasks without the constant interruptions of material handling. The robot’s advanced navigation and safety features make it a valuable asset on the floor, supporting a safer, more efficient workplace. Reliable Robots provides scalable, reliable technology to help manufacturing businesses stay competitive and increase output while reducing operational costs.

Automated Material Handling for Smarter Manufacturing

Reliable Robots offers innovative robots for manufacturing and material handling automation, designed to improve production efficiency and reduce operational costs. Our robots ensure smooth transportation of materials, from raw inputs to finished products, helping manufacturing businesses streamline their processes and stay competitive. By automating routine tasks, businesses can increase throughput and improve operational efficiency while enhancing workplace safety.

- Automate material transport to reduce manual labour and minimize downtime.

- Boost productivity by streamlining workflows and improving throughput.

- Reduce operational costs by using robots to handle repetitive tasks efficiently.

- Improve safety by minimizing human involvement in heavy lifting and material handling.

- Integrate easily with existing manufacturing systems for a seamless workflow.

- Achieve reliable, consistent results with advanced navigation and safety features.

- Scale operations with robots that adapt to growing manufacturing demands.

The S100 Delivery Robot: Boosting Efficiency in Manufacturing

Optimize your manufacturing facility with the S100, a heavy-load delivery robot designed to streamline material transport. Featuring multi-modal SLAM, dual LiDAR, and advanced vision technology, the S100 ensures precise navigation and real-time obstacle avoidance. With 360-degree detection and seamless IoT connectivity, it operates safely alongside humans, enhancing productivity and ensuring uninterrupted 24/7 operation with a quick 15-second battery swap. Learn more about how the S100 can enhance efficiency in your manufacturing operations.

PUDU T300

Smart Industrial Delivery Robot

Meet the PUDU T300, a powerful and efficient delivery robot built for factories, warehouses, and busy production floors. Designed to transport materials safely and quickly, this robot helps automate repetitive delivery tasks so your team can focus on higher-value work.

With advanced navigation powered by LiDAR and visual sensors, the T300 easily moves through narrow aisles and shared workspaces. It can operate in multiple modes — from fully autonomous delivery to follow-along or assisted transport — making it one of the most flexible options in its class.

Perfect for manufacturing facilities, logistics centers, and industrial environments looking to reduce labor costs and increase productivity, the PUDU T300 is a reliable, easy-to-deploy solution that keeps your operations moving smoothly all day long.

PUDU T600

Heavy-Duty Material Transport Robot

When you need serious power and precision, the PUDU T600 delivers. Engineered for high-load transport, this robot can handle up to 600 kilograms of materials with ease — making it ideal for factories, warehouses, and industrial logistics.

The T600 uses smart obstacle detection and intelligent scheduling to plan the most efficient routes, even in high-traffic environments. It can also integrate with elevators and doors, allowing for multi-floor operation without human assistance.

Whether you’re moving equipment, components, or finished goods, the PUDU T600 provides fast, safe, and dependable automation that saves time and reduces wear and tear on your workforce. It’s the next step toward a fully connected and automated facility.

PUDU SH1

Smart Upright Scrubber for Tight Spaces

The PUDU SH1 is a compact, high-performance robotic floor scrubber built for tight, hard-to-reach areas. From corners and edges to spaces under tables and shelves, the SH handles it all with precision.

Powered by advanced sensors and efficient battery technology, this upright scrubber combines strong suction, high brush speed, and minimal water use to deliver deep cleaning results with less waste. Its ergonomic design makes it easy to maneuver and ideal for commercial cleaning teams who need to cover detailed areas quickly.

If your facility needs consistent, thorough cleaning in compact or crowded spaces, the PUDU SH is a smart and sustainable choice that enhances both hygiene and productivity.

PUDU MT1

Autonomous Sweeping Robot with AI Detection

For large, open spaces, the PUDU MT1 brings AI-driven cleaning power to your floors. This autonomous sweeping robot uses intelligent recognition to detect and remove different types of debris — from dust and leaves to paper scraps — all without supervision.

Its advanced navigation allows it to map, learn, and adapt to your environment, ensuring full coverage across wide areas such as warehouses, shopping centers, and transportation hubs. The MT1 even features edge cleaning and obstacle avoidance, so it never misses a spot.

Built for long runtimes and continuous operation, the MT1 helps businesses maintain spotless floors while lowering cleaning costs and labor demands — making it an excellent long-term investment for facilities of any size.

SPARKOZ TN70

All-In-One Floor Scrubbing Solution

The SPARKOZ TN70 combines power and precision in one intelligent cleaning system. Designed for commercial and industrial spaces, this autonomous floor scrubber sweeps and scrubs floors in a single pass, leaving them spotless and dry within minutes.

Equipped with smart navigation and obstacle sensors, the TN70 can operate safely in dynamic environments such as malls, airports, hospitals, and schools. Its large tank capacity and efficient design allow for extended cleaning sessions with minimal downtime.

If you’re looking for a

high-efficiency robotic cleaner that delivers consistent results and saves on manual labor, the SPARKOZ TN70 is a proven solution that helps maintain a professional, polished environment every day.

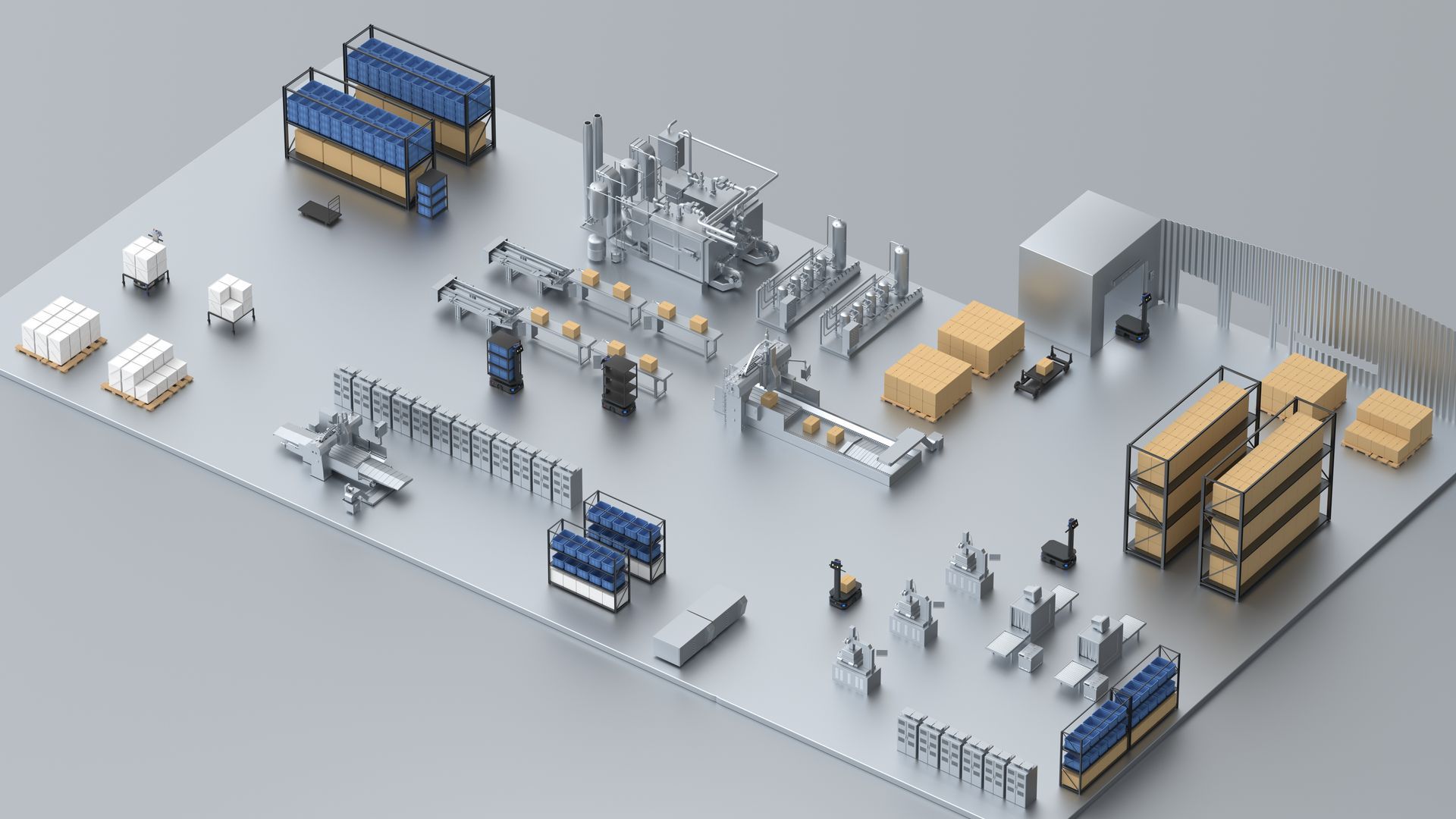

PUDU Robotics: Advanced Robotics for Modern Industrial Facilities

PUDU Robotics is a global leader in commercial service and industrial robotics, dedicated to improving productivity, safety, and operational efficiency across a wide range of industries. With over 100,000 robots deployed worldwide, PUDU combines advanced R&D, precision manufacturing, and industry-leading AI technology to deliver reliable automation solutions at scale.

Backed by nearly 2,000 authorized global patents and supported by top-tier robotics engineering teams, PUDU designs and builds robots that streamline logistics, cleaning, and on-site workflow operations. The company operates multiple large-scale manufacturing facilities and maintains rapidly growing global distribution and service networks.

Industries Served

- PUDU’s robotics technology is deployed worldwide in:

- Industrial Manufacturing & Warehousing

- Healthcare & Nursing Facilities

- Hospitality & Hotels

- Retail & Shopping Centers

- Education

- Entertainment & Sports Venues

- Residential & Office Buildings

- Transportation hubs & public services

Global Presence

- Operating in 60+ countries

- Installed in 600+ cities

- Supported by 700+ distributors worldwide

- Global subsidiaries in the USA, Netherlands, Singapore, Japan, and South Korea

- Three major factories with a combined production capacity of 150,000 robots annually

Industrial Delivery Robots

T300 Series – Heavy-Duty Industrial Transport Robots

The T300 series is a highly versatile industrial AMR (Autonomous Mobile Robot) designed for demanding factory environments. It supports multiple configurations—standard, tray, lifting, towing, and roller conveyor modes—making it suitable for complex production workflows.

Key Benefits

- Up to 300–400 kg load capacity (model-dependent)

- High-precision docking with ±1 cm accuracy

- Flexible deployment with no modifications required to the environment

- Automatic elevator riding & gate passing

- 8–12 hours of runtime with fast charging and optional battery swap

- Compatible with line-side racks, conveyors, pallets, totes, and custom material carriers

Essential Specs

- Load Capacity: 300–400 kg

- Max Speed: 1.2 m/s

- Navigation: VSLAM + LiDAR

- Battery Life: Up to 12 hours (unloaded)

- Minimum passable width: 60–75 cm

T600 Series – Ultra Heavy-Duty Transport (600 kg Capacity)

The T600 is engineered for extremely heavy industrial transport tasks and demanding workflows.

Key Benefits

- 600 kg payload capacity

- Built for large-scale factories, metalworking plants, injection molding facilities, and pallet transport

- Equipped with advanced LiDAR SLAM for high-accuracy navigation

- Fully autonomous with elevator and door integration

Essential Specs

- Payload: 600 kg

- Max Speed: 1.2 m/s

- Runtime: 12 hours

- Navigation: LiDAR + ceiling-based VSLAM (depending on model)

- Minimum passable width: 65–70 cm

Industrial Cleaning Robots

MT1 Series – High-Capacity AI Cleaning Robots for Large Factories

The MT1 lineup is engineered for large-scale cleaning tasks in production workshops, warehouses, and industrial campuses.

Key Benefits

- Professional cleaning for 100,000+ sq ft industrial areas

- AI-powered inspection, trash recognition, and spot-cleaning logic

- Multiple cleaning modes: sweeping, vacuuming, dust-pushing

- 24/7 autonomous cleaning with automatic charging and water refill options

- Handles dust, metal shavings, debris, fabric scraps, and production waste

Essential Specs

- Cleaning Efficiency: 18,000–65,000+ sq ft/hour (depending on mode)

- Trash Bin: 35 L capacity

- Runtime: 4–10 hours

- Navigation: VSLAM + 3D LiDAR + Marker SLAM

Use-Case Examples

Lithium Battery Manufacturing Facility

- 16 T300 Roller Robots

- 2,000+ transport trips per day

- Automated feeding, finished product transfer, and multi-point routing

- Real-time obstacle avoidance in dense production lines

Smart Home Appliance Plant (Two-Floor Facility)

- T300 fleet automates transportation across floors

- Integrated with elevators, gates, and call buttons

- Adapts to fast-changing production tasks

Battery Manufacturer – Line-Side Automation

- PuduBot 2 handles raw materials, semi-finished items, and waste

- MES-integrated item scanning and secure pickup

- Reduced manual material handling by 54%

Automotive Parts Factory

- T300 towing racks for diverse, irregular components

- Overcomes dynamic environments with high-precision navigation

Textile Factory

- MT1 robots manage high-volume lint, scraps, and thread debris

- 24/7 aisle cleaning for 5,000 m² production floor

Industrial Processing Plant

- CC1/MT1 robots clean over 40,000 m² of warehouse and workshop space

- Fully autonomous sweeping and scrubbing with scheduled cleaning

Frequently Asked Questions (FAQs)

What types of tasks can Reliable Robots' manufacturing robots perform?

Reliable Robots' manufacturing robots are designed to automate material handling tasks, including the transport of raw materials and finished products. This automation reduces downtime and ensures seamless workflow transitions in manufacturing environments.

How does the S100 robot enhance manufacturing efficiency?

The S100 robot features advanced navigation and safety systems, allowing it to operate safely alongside human workers. By automating material transport, it minimizes manual labor, reduces operational costs, and increases overall productivity.

Can Reliable Robots' solutions integrate with existing manufacturing systems?

Yes, Reliable Robots' automation solutions are designed to integrate seamlessly with existing manufacturing systems, facilitating a smooth transition to automated processes without disrupting current operations.

What safety features are incorporated into the S100 robot?

The S100 robot is equipped with multi-modal SLAM, dual LiDAR, and advanced vision technology for precise navigation and real-time obstacle avoidance. Its 360-degree detection system ensures safe operation in dynamic manufacturing environments.

How do Reliable Robots' solutions contribute to cost reduction in manufacturing?

By automating routine material handling tasks, Reliable Robots' solutions reduce the need for manual labor, minimize downtime, and enhance workflow efficiency. These improvements lead to significant reductions in operational costs.

Enhance Efficiency with Robots for Manufacturing

Stay ahead in manufacturing with the latest material handling automation trends. Subscribe to our newsletter to discover how robots for manufacturing can streamline your operations and reduce costs.

Contact Us Today for a Free Consultation and Discover How Reliable Robots Can Level-up Your Business.

Reliable Robots offers business automation solutions across Toronto (City Core), North York, Scarborough, Etobicoke, Mississauga, Brampton, Vaughan, Richmond Hill, Markham, Pickering, Ajax, Whitby, Oshawa, Milton, Oakville, Burlington, Hamilton, Aurora, Newmarket, Georgetown, and the Greater Toronto Area.