Pudu T Series

Meet the T Series Family

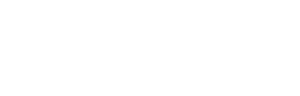

Pudu T300

The PUDU T300 Series includes the Standard, Lifting, Conveyor, Tray, and Towing versions, forming a versatile lineup of transport robots designed for material handling in industrial settings and heavy-load delivery in commercial environments. Built around a high-load chassis, the series features an open architecture and an onboard touchscreen for easy operation. With a maximum payload of up to 300kg, the robots also support essential IoT capabilities such as elevator control, e-gate passing, and paging function. The series offers extensive software and hardware interfaces, enabling seamless system integration and hardware expansion.

Key Features

Superior Mobility

Max. 300kg Load Capacity

Multi-modal Interaction

24/7 Non-stop Operation

Diversified Application Series

Flexible VSLAM+ Positioning

360° Omni-Sense Safety

ISO 3691-4 Standard

VSLAM+ for Rapid Deployment Across Vast Venues

This allows the PUDU T300 to quickly adapt to changes in production layouts without the need for time-consuming reconfiguration or facility remodeling.

IOT Capabilities

Equipped with expansive IoT capabilities, PUDU T300 supports elevator control, e-gate access, and various other smart connectivity solutions. Featuring multiple remote calling functions such as pagers and app-based calling.

24/7 Non-Stop Operations

Equipped with both automatic recharging and battery replacement options, it ensures uninterrupted service to fulfill round-the-clock operational requirements.

Versatile Application Series

The diversified application series significantly enhances the robot's adaptability and versatility, thereby increasing operational efficiency and simplifying procedures, ensuring a more efficient, smooth, and seamless delivery process.

Exceptional Mobility

Boasting an exceptional 60cm path clearance, the T300 ensures agile maneuverability in narrow human-robot cohabited spaces, effortlessly overcoming 20mm thresholds and 35mm grooves.

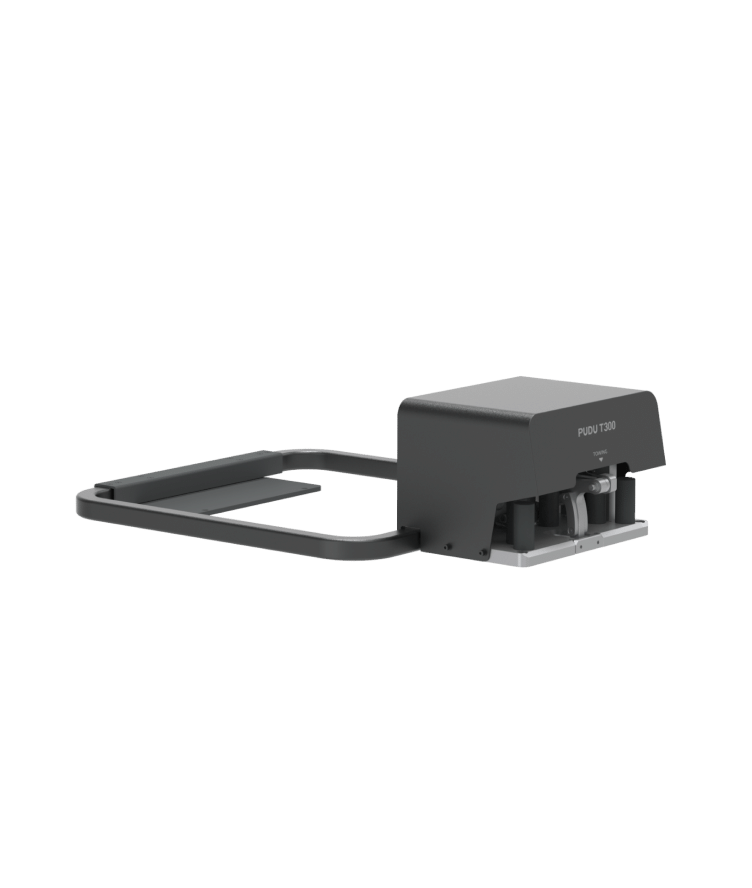

Accessories

Pudu T600 Series

The PUDU T600 is a heavy-payload industrial delivery robot designed for moving large payloads. Centered around a robust mobile chassis, it features a touch screen and handle for user-friendly operation. Features: Equipped with a built-in screen, it can be operated directly without a central control system. Includes a power-assist switch, quick-access buttons, and front indicator lights for easy and efficient use.

PUDU T600 Underride

The PUDU T600 Underride Version is a chassis-based industrial delivery robot. With a low-profile design, it can navigate beneath racks and lift them autonomously for material handling. Features: Compact form allows it to travel underneath rack units, enabling flexible navigation. Capable of lifting cargo from the center underneath, requiring minimal path clearance.

loT-Enabled Connectivity

- Integrated PLC communication for automated material pickup/delivery notifications.

- Supports access control, autonomous elevator integration, and self-networking callers. Modular integration into production workflows without complex system modifications

Flexible & Multi-Functional Applications

- Supports "Human-to-Line," "Line-to-Line," and "Line-to-Human" material transfer modes.

- Compatible with manual/automated loading and unloading.

Enhanced Safety Compliance

Meets ISO 3691-4 standards. Multi-layered safety: LiDAR, vision systems, safety bumpers,s. and in-position sensors to monitor material placement.

Precise & High-Efficiency Material Handling

- Accuracy: ±0.4 inches (110 mm)

- Capacity: Single-layer load up to 176 lbs (80 kg); expandable to double-layer rollers for 352 lbs (160 kg) total capacity.

Adjustable Dimensions for High Adaptability

- Length: Up to 25.6 inches (650 mm)

- Width: Adjustable from4.7 inches (120 mm) to 21.3 inches (540 mm)

- Height: Adjustable working surface height (12.0-43.3 inches /305-1100 mm)

- Orientation: Roller direction adjustable for multi-angle docking.

Product Specifications

| Category | T300 Standard | T300 Tray | T300 Lifting | T300 Towing |

|---|---|---|---|---|

| Machine Weight | 65kg | 103kg | 81kg | 90kg |

| Loading Capacity | 300kg | 300kg | 300kg | 400kg, (200kg Counterweight) |

| Max. Speed | 1.2m/s | 1.2m/s | 1.2m/s | 0.8m/s |

| Path Clearance | ≥60cm | ≥60cm | Determined by load size | Determined by load size |

| Threshold Overcoming Height | 20mm | 20mm | 20mm | 5mm |

| Groove Crossing Width | 35mm | 35mm | 35mm | 35mm |

| Run-time (No Load) | 12h | 12h | 12h | 12h |

| Run-time (Full Load) | 8h | 8h | 8h | 6h |

| Dimensions | 835mm * 500mm * 1350mm | 835mm * 500mm * 1350mm | 835mm * 500mm * 1350mm | 835mm * 500mm * 1350mm |

| Charging Time | 2h(0% to 90%) | 2h(0% to 90%) | 2h(0% to 90%) | 2h(0% to 90%) |

| Navigation Methods | VSLAM & Lidar SLAM | VSLAM & Lidar SLAM | VSLAM & Lidar SLAM | VSLAM & Lidar SLAM |

Streamline Hospitality with Reliable Robots

Stay informed on the latest in robotic automation solutions for hospitality. Subscribe to our newsletter for insights, updates, and innovations for your business.